How Do Freight Shipping Seasons Affect Your Business?

Melton Logistics – 07/29/2024

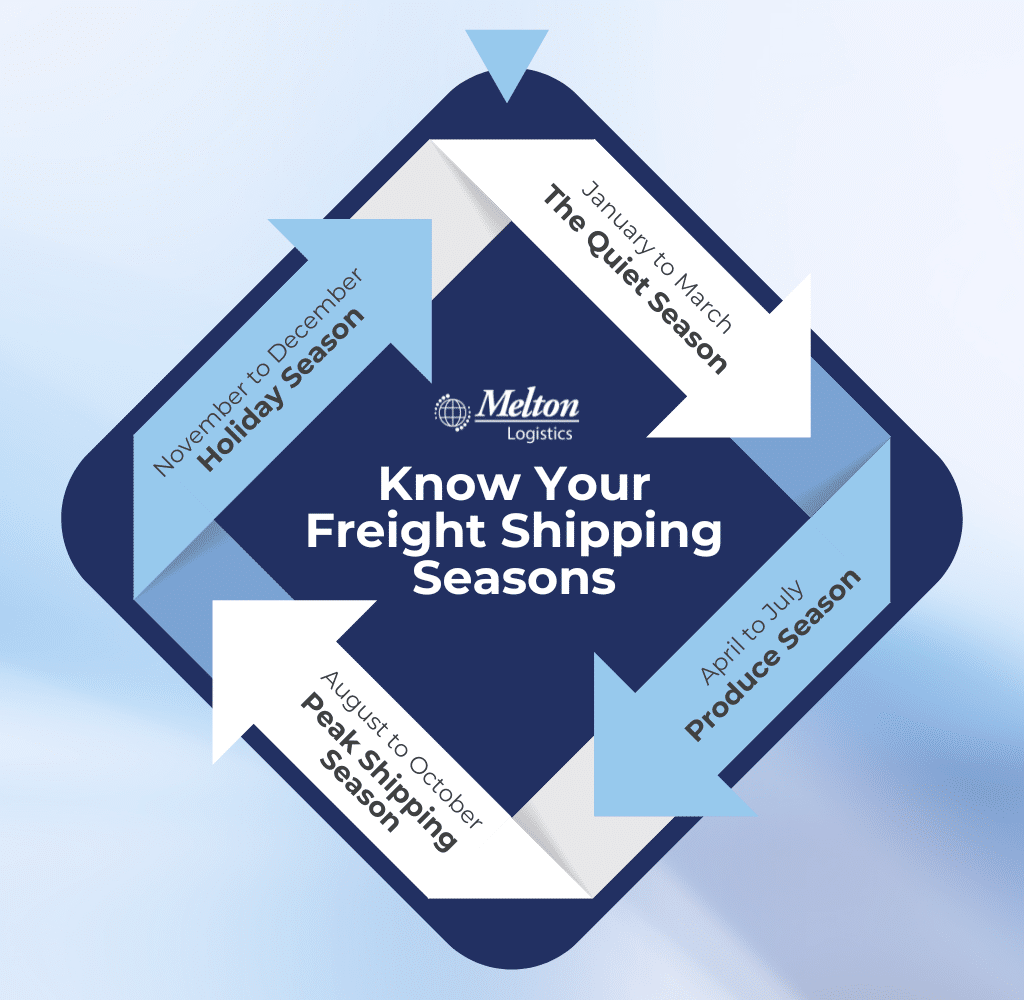

As with many industries, trucking is no stranger to cyclical economic peaks and valleys in volume and demand. Shifting demands in the market can impact production and shipping times, rates, available trucks, and much more. Understanding these demand swings can help optimize your supply chain management and lead to an effective shipping experience for your customers.

Depending on the market you find your company operating in, there can be more minute changes in the landscape than what we cover here (such as with produce and agriculture vs. construction and building materials). But overall, shipping seasons tend to follow a general pattern, often dictated by the season itself.

Click to enlarge.

January to March: Quiet Season

At the beginning of the year, the logistics and transportation industry can expect to see a drop in demand. Following the holiday highs, several industries may take this period to slow down or halt their productions, which can cause lower demand across the board and bring rates down significantly. This is also when the snowy season peaks across the U.S., making shipping more difficult and hazardous.

April to July: Ramp-Up Season/Produce Season

Shipping starts to pick up across the board as many businesses resume operations during this season. Spring also means the start of harvest season, and agriculture needs can further amplify the volume that logistics companies need. For carriers that deal in food products or produce, your company may expect to see fewer available trucks, which can directly impact the market rates.

August to October: Peak Shipping Season

While the produce season continues in late summer and early fall, this demand tends to decline around October. Carriers that haul consumer goods will begin to see demand climb as consumer demand surges during these times in anticipation of back-to-school and the holiday season. This can drive up shipping volume and rates, even more so for any carriers that diversify their freight amongst multiple markets.

November to December: Holiday Shipping Season

One of the final hurdles of the peak season is the hectic few months of holiday shipping. Wholesalers, big box retailers, and manufacturers alike are in a constant state of movement to keep up with demand, and the transportation and logistics industries may see a sharp increase in handling larger and multi-load requests, some with far stricter deadlines than previously experienced as shippers rush to complete shipments before the new year.

From a carrier’s perspective, the cyclical nature of shipping seasons can be used as a guide to plan base rates and increase capacity. As the seasons progress and the volume increases, it’s important to understand that extra attention is going to be necessary to manage the larger details and navigate unexpected delays.

For shippers, it’s important to plan for a multitude of hurdles as you navigate these seasons: rate hikes, limited availability, supply chain disruptions, and potential delivery delays. Even if your industry is not directly affected by a stage of the cycle, peak seasons might affect overall capacity and rates as carriers become busier. Take advantage of contract rates and spot rates depending on your situation and the market’s situation; read more about contract and spot rates on our blog here.

No matter the industry, Melton Logistics can help you with your freight needs. Check out the services we offer here.